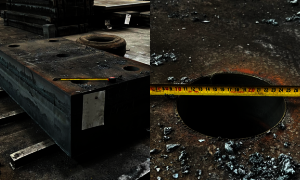

Thick plates, small holes

Internal contours can sometimes be problematic when flame cutting. In particular, the size of the inner contour or borehole can mean that it cannot be cut.

However, the problem here is not the largest dimension of the internal cut-out required, as is usually the case, but the smallest dimension. As a rule, bore diameters that are larger than the plate thickness can be cut without any problems. Smaller boreholes, on the other hand, have to be considered critically and are not always feasible.

With the appropriate expertise, we can still produce boreholes of this sort using burner technology, depending on the machine equipment, the burner, and the position in the flame-cut part. Bore diameters of up to half the plate thickness are then possible. If even smaller diameters are required, this first needs to be reviewed technically by our specialist department. As there are many parameters to consider, each borehole needs to be tested and assessed individually. This approach has already enabled us to create bore diameters of up to a quarter of the plate thickness.